Pipe of the Year

- jwh784

- Sep 2, 2020

- 6 min read

You probably are familiar with the Pipe of the Year as a concept, maybe even have a few in the rack. Some makers offer them — Mark Tinsky’s annual Christmas pipe comes to mind — and clubs often commission them. I made one in 2014 for the Seattle Pipe Club and two for Neill Roan’s Passion for Pipes blog site before that, and recently completed one for the Cigar Family Lounge internet forum. Because that last group of pipes has dominated my waking hours for the past week I really don’t have much else to write about.

There will be no attempt to recount the process of making a group of pipes that are as nearly identical as possible step by step; more readers are better than fewer, and you can make emptying a bathtub with a spoon sound only so interesting.

My first pipe of the year was a recreation of the Comoy’s Blue Riband shape 283 (if you don’t have Neill’s Comoy’s book, you should), for Passion for Pipes. With a total close to 40 pipes, that was definitely jumping into the deep end and the project all but consumed a summer.

The second P4P, a Blue Riband shape 284, below, was a slightly smaller batch. Only showing the blasts. The wide, angled rim of a Rhodesian is like flypaper for flaws, so I had to allow myself some slight variation in the shape to make it happen.

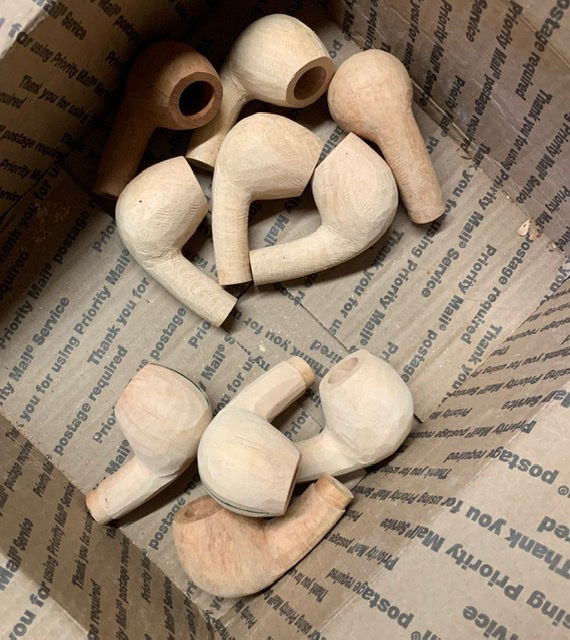

The Seattle pipe, an Acorn, was . . . thought it was more but looks like eight pipes, and the Cigar Family pipe is nine. Not a bad number.

When you make one pipe, you get in a flow. One thing happens, then the next thing, then you do something else, and then the pipe is done. Yes, it has taken some hours, but the scenery has changed relatively quickly. Making a batch of pipes is a different sort of flow, like driving across Kansas at 15 mph instead of 80. Maybe that sounds like a bad thing, but it’s all how you look at it. When you do one thing nine times in a row (or 40) you have greater motivation to examine the process. An inefficiency that costs five minutes and seems insignificant when you do it once becomes a problem worth solving when you do it over and over. Could I have removed more material with a coarser tool? Can I set a travel stop on the lathe so I don’t have to sneak up on a measurement and can’t overshoot? Would a differently ground cutter leave a better finish and save sanding? Can I make a jig to hold this stummel to make sanding easier on my hands? You also have to think and plan your order of operations carefully, because if you do the wrong thing nine times . . . Every time I’ve made a batch of pipes it has refined my process, sometimes subtly, sometimes markedly.

If making a batch one step at a time sounds boring, certainly the option exists to make nine individual pipes in a row, and I’m not sure it would be all that much slower. Uniformity, though, is of paramount importance. Sure, the club wants a handcrafted pipe and all that, but, sooner or later, two or more club members will be together and will compare pipes. With an internet group it could be even worse; they could all post pictures. You don’t want anybody to think, “Awwww, man, why did I get the (fill in the blank with any conceivable variation) one?” If you do each operation sequentially to all the pipes as a group, you remove as many variations as possible. Some variations you can’t. No two pieces of briar will have the same grain or exactly the same density, it’s just the way it is. You do your best.

A POY makes you count. X pipes must be finished. There will be F flaws so X+F blocks will be needed, and once you start keeping score the briar cost becomes real. Making one pipe, sometimes you can call an audible — make a smaller pipe or a bigger chamber or a different shape or finish. If none of that works, just chuck it in the trash and forget it ever happened. When you have X=9 pointed at your head and uniformity is required, F becomes a whole number. I started with a dozen blocks, bandsawed into flaws on two. F=2. Replaced them, lost two to flaws in the chamber, F=4. Down to one spare, shaped into two big flaws on the wheel, needed to go back to the lathe and replace those, F=6. After fine shaping, F=9. Maybe a couple of those are recoverable as other shapes, so let’s say F=7. I didn’t really want to know that, but you see how it happened. Out of a dozen blocks, bandsawing into two huge flaws is not all that bad. If you’re boring a dozen chambers and only two have flaws right at the specified diameter, who can complain about that?

And so on, but it explains why, if you were unfortunate enough to be in my head with me during certain operations, you might have heard a stream of obscenity that would make Sergeant Hartman blush. “Oh, no. Ooooh, no you don’t. NOOOO! You blanking piece of blank, you did not just blanking DO THIS TO ME. BLANK you! Whew, it’s going away. Oh, no it’s not. Blank! Blankity blanking blank blank.” And when I sanded into a flaw in the rim with 400 grit on a pipe that was ready for blasting and had to go all the way back to square one . . .

Actually, the frustration had been beaten out of me by that point, or I had become more philosophical, or maybe those are the same thing. I started thinking about the expression “no use crying over spilled milk,” how that saying didn’t make much sense when I first heard it as a child because I didn’t even like milk, but my mom told me about growing up in Oklahoma on a farm with an outhouse and only one electric light, about milking Bessie the cow by hand and how spilling a full bucket of milk meant not only the wasted work but that the whole family was out of milk until the cow made more of it. I thought about the Christmas when I was maybe seven or eight. My dad was trying to teach me about money and had given me $20 to buy gifts for everyone, the idea being that I would learn how to shop and prioritize and budget. That was a lot of money in the mid-70s, especially for a public school teacher probably making less than 15 grand a year, and when we got to the SeaTac Mall in Tacoma and I put my hand in my pocket the money was gone.

My father’s shoulders sagged a bit, and my shame and sense of failed responsibility remains heavy and sharp fifty years later. He didn’t get angry; he must have asked himself what the hell he was thinking trusting a seven-year-old with a twenty. He didn’t punish me, and he never spoke of it again. There are parents who, decades later, would be saying, ”Here, take my credit card, but don’t go screwing around and lose it like you did your Christmas money.” The mark left by that episode has changed shape over the years. It’s easy to get caught up in the moment and attach a whole lot of importance to things like pipes or twenty-dollar bills, and either cause or experience unnecessary pain. Yes, it’s too bad about the time/money you just lost, but what can you do about it? More to the point, what shouldn’t you do just because you’re mad? “There’s many a slip ‘twixt the cup and the lip,” as my dad used to say, and I still marvel at his perspective.

This isn’t where I thought the story of the Cigar Family POY would finish; it seemed more likely that we would wind up on metrology or down some other rabbit hole. Hard to know if it’s good blogging or not to drag you along as I meander around to reminding myself not to get all wound up about things that not only can’t be changed, but are nobody’s fault and probably aren’t that big a deal anyway. Like a flaw in a nearly finished pipe — it’s not worth an ulcer, just make another one. But here we are. If you ever lost your Christmas money, maybe you understand.

I have one of those first POYs you did, the blasted #24 of Neill's 283. I didn't realize they were your first POY. Amazing! I got out of pipe smoking shortly after, so it still sits unsmoked in my pipe cabinet, next to the unsmoked nose warmer you made for me in 2009. Reading all your posts has got me itching to start smoking again. Maybe I'll finally have to break them in, because I'll certainly never get rid of them. Thanks sir!

Oh yes, I do. :-)